The need to clean up contaminated sites is not just an environmental priority; it is essential for public health. Gas thermal remediation is becoming a promising solution, especially in removing volatile organic compounds (VOCs). In a recent case study from Marietta, Georgia, a clever in-situ thermal remediation strategy was applied to tackle this pressing issue. This approach not only demonstrated remarkable effectiveness but also set a precedent for future sustainable remediation methods. Let's take a closer look at the methodology and results of this successful project.

Background: The Challenge at Marietta

In Marietta, Georgia, a site was found with heavy contamination from VOCs, particularly from trichloroethylene (TCE) and cis-1,2-dichloroethylene (CIS-1,2-DCE). The pollutants were located in complex areas, including beneath buildings, roads, and neighboring properties, demanding a unique and careful remediation plan.

To efficiently remove these VOCs from the soil, a target treatment temperature of around 100°C was necessary. However, the presence of critical underground utilities made the challenge even more complicated. The remediation needed to avoid any disruption to these services and minimize disturbances to daily activities in the area.

Methodology: In-Situ Thermal Remediation Strategy

Selection of Thermal Remediation

Considering the serious level of contamination, an in-situ thermal remediation strategy was chosen. This method allows for heating the soil in place, eliminating the need for extensive excavation. By using gas thermal remediation, the team could reach the necessary temperature to volatilize the VOCs while keeping the disruption to infrastructure and community activities at a minimum.

Design and Implementation

The approach included installing angled wells placed thoughtfully to treat contaminated areas beneath buildings and roads. This design ensured effective heating while preventing interference with traffic and daily activities.

To complement the thermal remediation, a system known as Heat Enhanced Anaerobic Bioremediation and Recirculation (HEABR) was integrated. This system was set up to inject nutrient-rich carbohydrates during and after the heating phase. By recirculating these nutrients around the heated zone, it supported the natural breakdown of any remaining contaminants, allowing for a dual method of both thermal and biological remediation.

Execution of In-Situ Thermal Remediation

The project took 134 days to execute. During this period, specialized equipment efficiently heated the contaminated soil, maintaining the target temperature of 100°C for optimal VOC removal.

Results: Achieving Remediation Goals

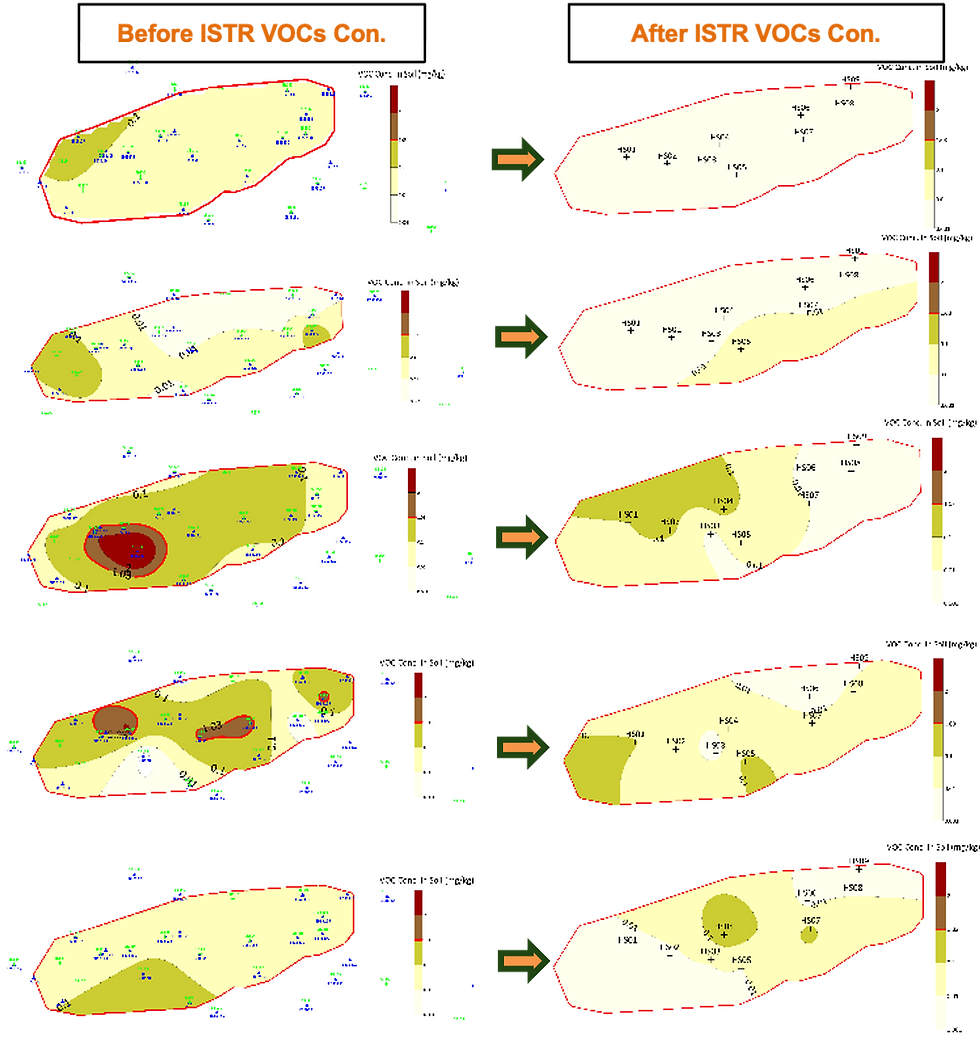

The thermal remediation project in Marietta achieved outstanding results. By effectively integrating in-situ thermal remediation with multiphase extraction (MPE) and soil vapor extraction (SVE), the team successfully dried the soil while reaching targeted heating levels.

Significant Contaminant Removal

In total, over 99% of the VOC mass was removed from the site, easily meeting the established remediation goals. This accomplishment reflects the effectiveness of combining thermal heating with additional technologies.

Key Data from the Remediation:

Treatment Area: 2,489 ft²

Treatment Depth: 50 ft

Geology: Silty clayey sand, saprolite/weathered bedrock, and un-weathered bedrock

Contaminants: TCE, CIS-1,2-DCE

Target Temperature: 100°C

Heating Period: 134 Days

Remediation Results: Below remediation goals

Soil sampling after the project confirmed that the site had achieved all defined remediation goals, indicating the project's success.

Implications and Future Considerations

Economic and Environmental Benefits

The success of this project offers important implications. First, thorough contamination removal can significantly boost property value and enhance public health safety. By efficiently eliminating VOCs, the project helps reduce health risks linked to prolonged exposure to these harmful pollutants.

Additionally, this project illustrates that complex contaminant scenarios can be managed without harming existing infrastructure. This establishes a viable model for future remediation projects with similar challenges.

Integration with Other Technologies

The combination of HEABR systems with traditional thermal remediation techniques points to exciting advancements in site clean-up methodologies. Following up thermal treatments with bioremediation maximizes the degradation of contaminants, providing a comprehensive approach to site remediation.

Reflection on the Successful Project

The successful case study in Marietta, GA, highlights how innovative strategies can effectively address VOC contamination. Using gas thermal remediation alongside bioremediation has proven to be a forward-thinking approach, addressing urgent environmental concerns while building healthier communities.

As technology continues to develop, experiences from this project will undoubtedly enhance future remediation efforts. By knowing how to balance site utility and community involvement, we can create improved designs that effectively address environmental restoration goals.

With ongoing research and practical application of these methods, the field can look forward to a future where contaminated sites are rehabilitated effectively. This not only protects our environment but also promotes public health for current and future generations.

Comments